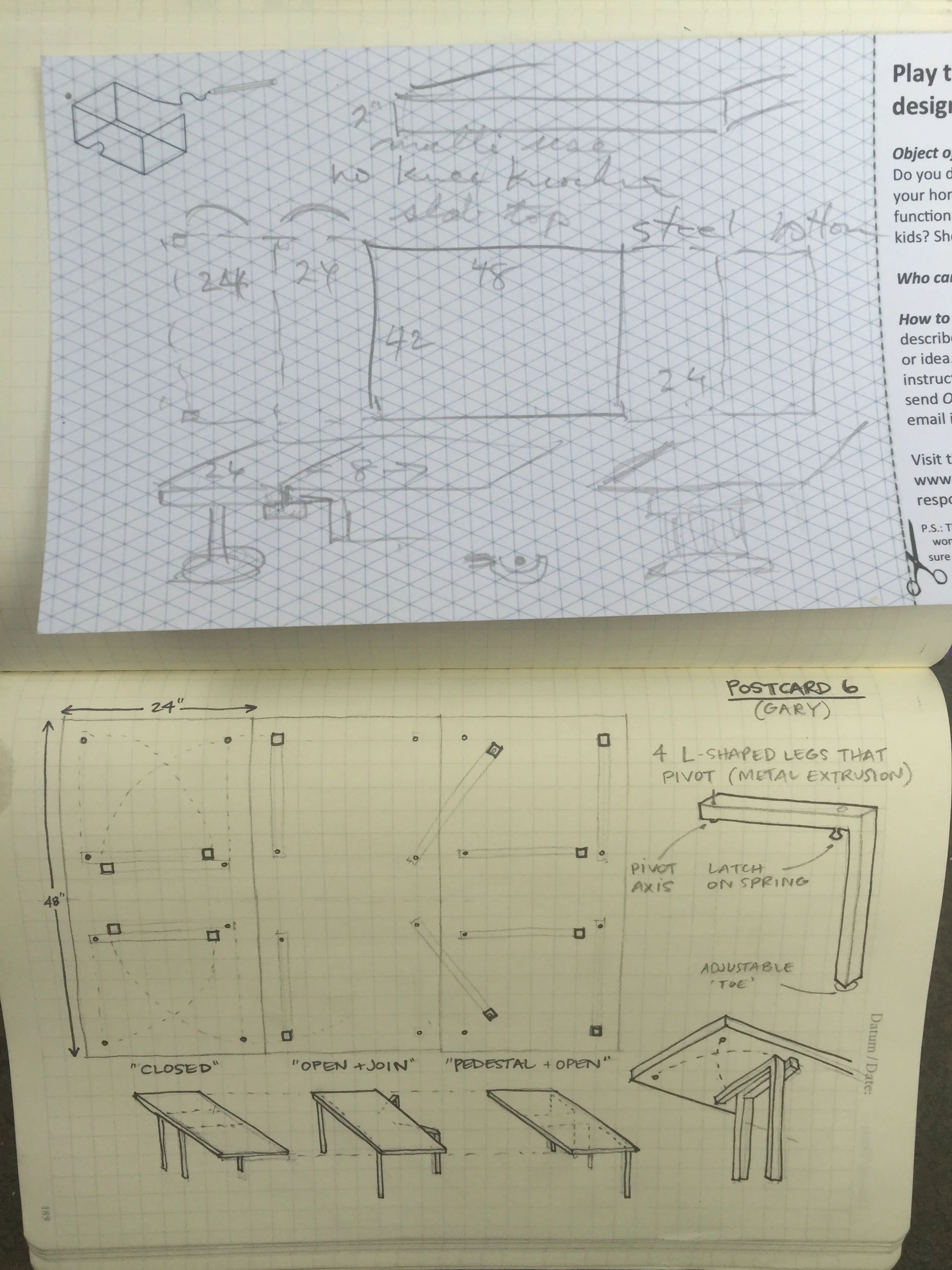

{Postcard 6} - "How can I design metal legs for an multi-use table to avoid knee knocking?" Submitted by Gary

{Postcard 6} - "How can I design metal legs for an multi-use table to avoid knee knocking?" Submitted by Gary

Gary is a woodworker and hobbiest furniture builder. He is building a large custom dining table out of rectangular slabs of wood and is stuck on how to fashion metal legs to support them and requested some design problem solving. He wants a small table for everyday family use, but the ability to have other narrower tables he can move around for bigger gatherings. He doesn't want the obvious pedestal styled bottom because he "thinks that the stability of the length would not be good if people lean on or put too much weight toward the ends."

This industrial design challenge includes:

- several identical 2'x4' wood slab table tops

- that need be able to stand on their own as side tables elsewhere in the home when separated

- be able to be joined together to form a large dining table

- allow for flexible dining seating with no 'knee knocking' on table skirts or legs

One idea is to make several L-shaped (extruded metal) legs that work by pivoting and latching in place. With four legs per table, each can be rotated out from a 'closed' pedestal position to several configurations. Latch holes can be drilled from the underside along the routered arc of the leg to enable latching into a traditional 'open' position at the corners, as well as to diagonally connect and support the adjacent table. The legs can be positioned to stay out of the 18 inches needed for knee clearance. Magnet and plates can be installed flush inside the edge of the table for added connectivity, and the adjustable 'toe' to the table leg can make up for any surface discrepancies.

~Deborah